Only a material like graphite – with its thin, lightweight, flexible, fire retardant, and thermal conductive properties – can be the driving force behind some of the most innovative products in the world today. From markets like consumer electronics and automotive to building and construction and manufacturing, graphite is making the impossible possible. Learn more about how NeoGraf is developing novel solutions for each market in very unique ways.

Change Drivers

Our world is evolving rapidly, and its technological advancements will have wide reaching implications across many industries. At NeoGraf we see these global megatrends fueling our growth for years to come. It’s no surprise that the world’s largest companies trust us to deliver material science breakthroughs taking their technology to new levels.

NeoGraf and the Graphene Market

NeoGraf Solutions, LLC has long been actively involved in producing and investigating advances in the high performance graphite market. Examining the potential benefits of graphene for a wide array of industries and products is [...]Learn More

Innovative Graphite Materials for Medical and Diagnostic Devices

The thermal requirements of medical devices are unique in the electronics industry. For example, the OLED screens of a medical device often use color to determine a diagnosis, so these colors must be completely [...]Learn More

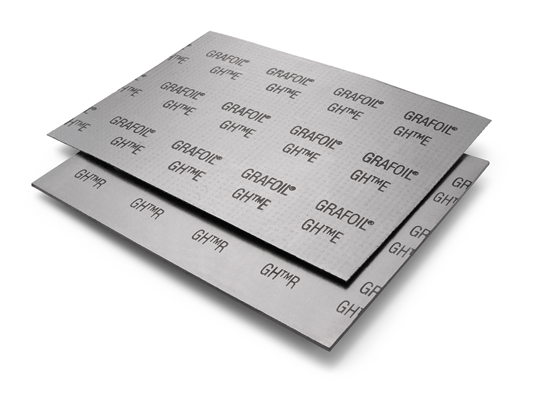

GraFoil® Sealing Solutions Help to Stabilize Infrastructure During the COVID-19 Pandemic

Introduced to the marketplace in 1967 as the first original flexible graphite technology, GRAFOIL® products have long been used in a wide array of applications across many industries. A superior gasketing material solution for [...]Learn More

Science

To us, graphite is more than a crystalline form of carbon with hexagonally arranged atoms – it’s the mineral around which we have innovated for the past 140 years. Graphite is a key ingredient and functional component in many products – from communications to energy, consumer electronics to transportation, and beyond. It’s the reason why some of today’s most technologically advanced products are successful and work the way they do.

Thermal Management in Batteries Used in the UAV and eVTOL Industries

The UAV and eVTOL industries have experienced significant growth over the past decade, driven by advancements in technology and increasing applications across various sectors, including military, agriculture, logistics, surveillance, and entertainment. These advancements have led to improved performance and safety of UAVs and eVTOLs, including the critical battery systems that power these aerial vehicles. The engineers and the R&D team at NeoGraf Solutions, continue to find the best graphite thermal management solutions for this rapidly evolving market. Learn More

Graf-M™ Graphite Masterbatches Enhance Performance in a Wide Variety of Applications

NeoGraf Solutions' Graf-M™ masterbatches represent a cutting-edge approach to enhancing polymer performance through the incorporation of graphite-based additives. These innovative products combine pelletized masterbatches and dispersions with NeoGraf's Graf+® graphite powders, Graf-X™ graphene nanoplatelets, and GrafGuard® expandable graphite flakes, offer manufacturers a powerful tool to elevate their materials' capabilities and simplify the manufacturing process. […]Learn More

Battery Pack Thermal Propagation Control Strategies in Electric Vehicles Using SpreaderShield™ Flexible Graphic

An emerging trend over the last two to three years has been to add layers of thermal insulation and flame/gas impingement barriers between the pouch and prismatic format cells in a battery pack to prevent thermal propagation. This passive thermal management solution has been shown to effectively prevent propagation without adding excessive weight to the battery. The obvious downside of this method is that the battery cells are surrounded by insulation, and there is no easy path for the internal heat of the cells to spread to the environment outside of the pack. How do you fix the problems caused by using an insulation-only strategy? It’s simple: Add NeoGraf Solutions’ SpreaderShield™ thin, flexible, and lightweight graphite heat spreader to the battery pack. [...] Learn More

How We Work

At NeoGraf, we are leaders in thermal management, pushing graphite to new horizons through hard work, persistence, ingenuity, and an undying belief that we can make the future better. We are a market-driven company that strives to understand the unmet needs of our industry. In doing so, we build strong relationships with our customers, becoming their trusted advisors. It’s our entrepreneurial attitude and innovative approach in R&D, product development, manufacturing, and process improvement that we leverage to bring products, technologies, and success to our global stakeholders.

Resources

As experts in the field of graphite material science, we have an abundance of resources to share across our product lines. From technical and safety data sheets, to certification and policies, feel free to peruse our library of useful information.

GraFoil® material was first introduced in 1967 as the original flexible graphite technology. This graphite foil was quickly utilized as the first fluid sealing material made exclusively from pure, natural graphite flake. Its resistance to heat, fire, corrosion, and aggressive chemicals makes it the most universally applicable sealing solution in the market today.

eGraf® SpreaderShield™ flexible graphite heat spreader materials are a unique line of products capable of cooling a hot component, protecting a temperature-sensitive component, reducing a thermal gradient, or preventing a surface hot spot. SpreaderShield flexible graphite is a thermal material ideal for a wide range of electronics applications, from the thinnest and lightest smartphones to high-power devices.

GrafGuard® expandable graphite flake is a non-halogenated fire retardant additive for materials that require improved fire-protection characteristics. It can be found in building materials and automotive applications to meet increasingly stringent fire safety codes. GrafGuard materials also improve the performance of fire-retardant additives such as phosphates, magnesium hydroxide and nitrogen compounds.