Engineered Graphite Additives Enhance Performance in a Wide Variety of Applications

NeoGraf Solutions, LLC offers a variety of masterbatches incorporating its Graf-X™ graphene nanoplatelets, Graf+® graphite powder, and GrafGuard® expandable graphite additives.

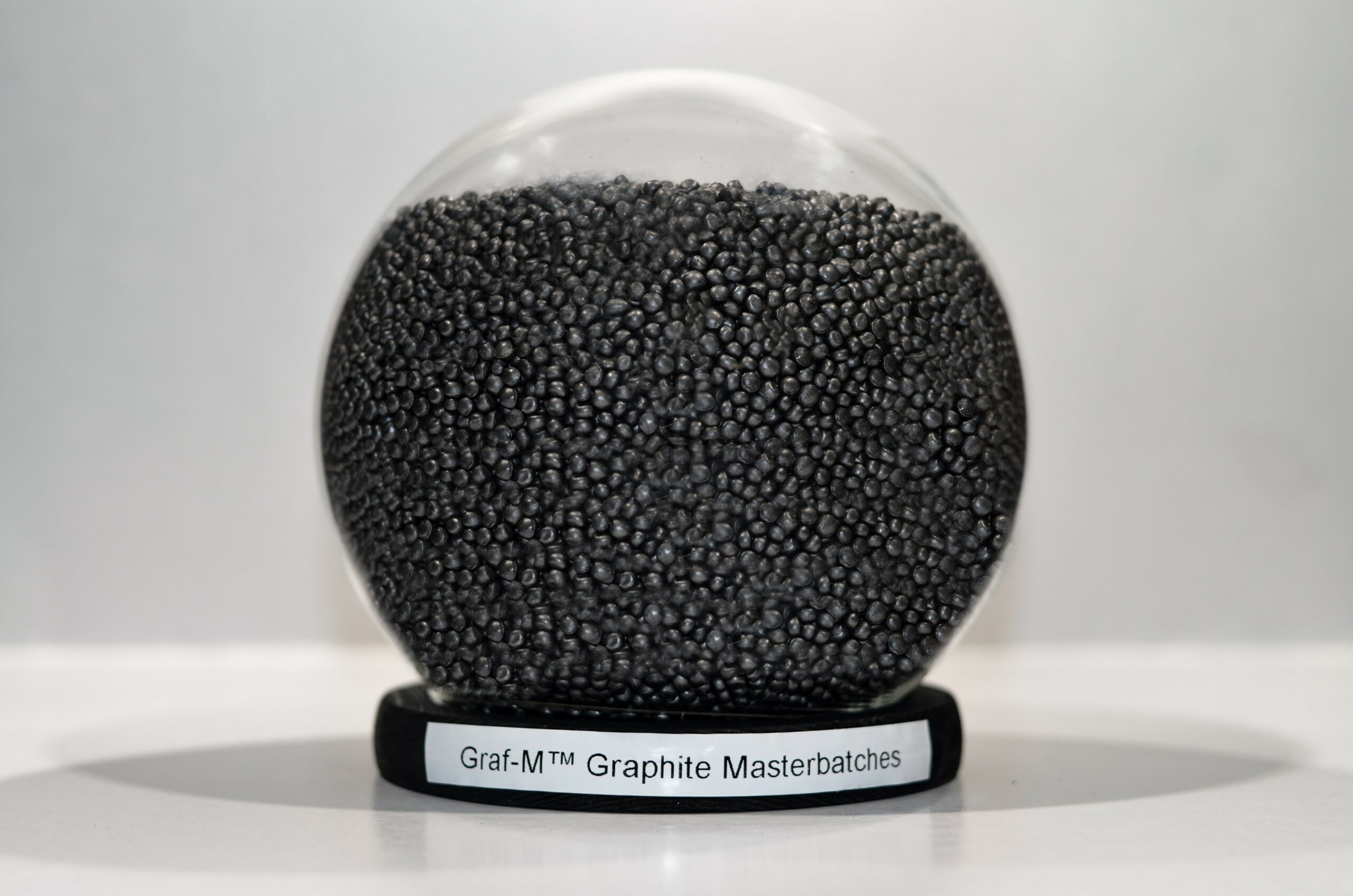

Why Graf-M™ Graphite Masterbatches

Graphene, graphite, and expandable graphite additives can be added to polymers to boost their electrical, thermal, mechanical and fire-retardant properties. The use of masterbatches is favored by customers who prefer the convenience of handling pellets rather than powders in their manufacturing processes.

Graf-M™ Product Portfolio

Material grades have been developed for the insulation board market. Properties of the three grades are available at TDS618.

- Graf-M EPS (01) for expanded polystyrene (EPS) insulation boards

- Graf-M XPS (01) for extruded polystyrene (XPS) insulation boards

- Graf-M XPS (02) for extruded polystyrene (XPS) insulation boards

Fire retardant (FR) grades have been developed for the polyolefin foam and thermoplastic markets, all using an LDPE carrier and 50% expandable graphite loading.

Properties of the four FR grades are available at TDS617.

The nomenclature is Graf-M FR (resin type) (Onset Temperature (°C)-Mesh Size)

- Graf-M FR (resin) (Grade)

- Graf-M FR (LDPE) (200-100)

- Graf-M FR (LDPE) (210-200)

- Graf-M FR (LDPE) (250-50)

- Graf-M FR (LDPE) (280-50)

Other formulations can be available on request.

Applications

Graf-M™ masterbatches are used in the building and construction, transportation, automotive and bedding industries

- In the manufacture of insulation boards (“Grey Board”) to increase their insulation value and reduce degradation to UV radiation. An increase in insulation value of ~ 20% can be accomplished with a graphite loading level of ~ 2-6 %.

- In the manufacture of polyolefin foams and thermoplastics to increase fire retardancy

NeoGraf’s global team of application engineers specialize in developing and manufacturing high-quality flexible natural and synthetic graphite material solutions for today’s advanced applications. Regardless of your product design phase (concept, prototyping, or mass production), we offer technical answers and thermal modeling support to some of your most challenging problems with a fast response time.

Media

Graf-M™ Graphite Masterbatches Enhance Performance in a Wide Variety of Applications

NeoGraf Solutions' Graf-M™ masterbatches represent a cutting-edge approach to enhancing polymer performance through the incorporation of graphite-based additives. These innovative products combine pelletized masterbatches and dispersions with NeoGraf's Graf+® graphite powders, Graf-X™ graphene nanoplatelets, and GrafGuard® expandable graphite flakes, offer manufacturers a powerful tool to elevate their materials' capabilities and simplify the manufacturing process. […]Learn More

GrafGuard®: The Non-Toxic, High Performing Alternative for Fire Stop Applications

Overview Growing concern over environmental sustainability continues to drive the introduction of stringent regulations that affect nearly every industry and product. Reducing adverse environmental and health effects is of particular interest when examining manufacturing [...]Learn More

Markets

Safety Data Sheets

Sell Sheets

Technical Data Sheets

What Our Customers Are Saying …

“Orders are always on time, never any issues with supply.”

“Dave Stuart (NeoGraf Research Scientist) has great expertise, and is always willing to help with technical problems, literature requests, or analytical tests. He is very responsive despite the different time zones and we appreciate his effort in coming to visit our sites regularly.”

“I was impressed with NeoGraf from a technical perspective and their speed of response.”

“NeoGraf was proactive in making improvements we didn’t even ask for.”

“NeoGraf showed us other applications in battery to enhance thermal (cell-to-cell) barrier performance which we had not considered.”