Next-generation electric vehicles (EV), electric airplanes (ePlane), and marine battery systems require rapid charging, high energy density, safety, and long lifespans. For this, they need thermal-management materials that are thin, lightweight, and durable. These materials must not only cool the cells during harsh charging and operating conditions but also prevent propagation in case of a cell failure. SpreaderShield™ flexible graphite is used as cooling fins between the cells of a pack or module. It directly replaces bulky, heavy aluminum fins in these lithium-ion battery packs, where being lightweight, compact, and safe is essential.

Applications

In EVs, ePlanes, and maritime battery systems, traditional thermal management metals, like aluminum, produce battery modules and packs that are too thick and heavy to be practical. SpreaderShield flexible graphite cooling fins directly replace aluminum to:

- Extend cell lifetimes

- Enable fast charge and discharge operations

- Prevent propagation if a cell fails

SpreaderShield™ Flexible Graphite Overview

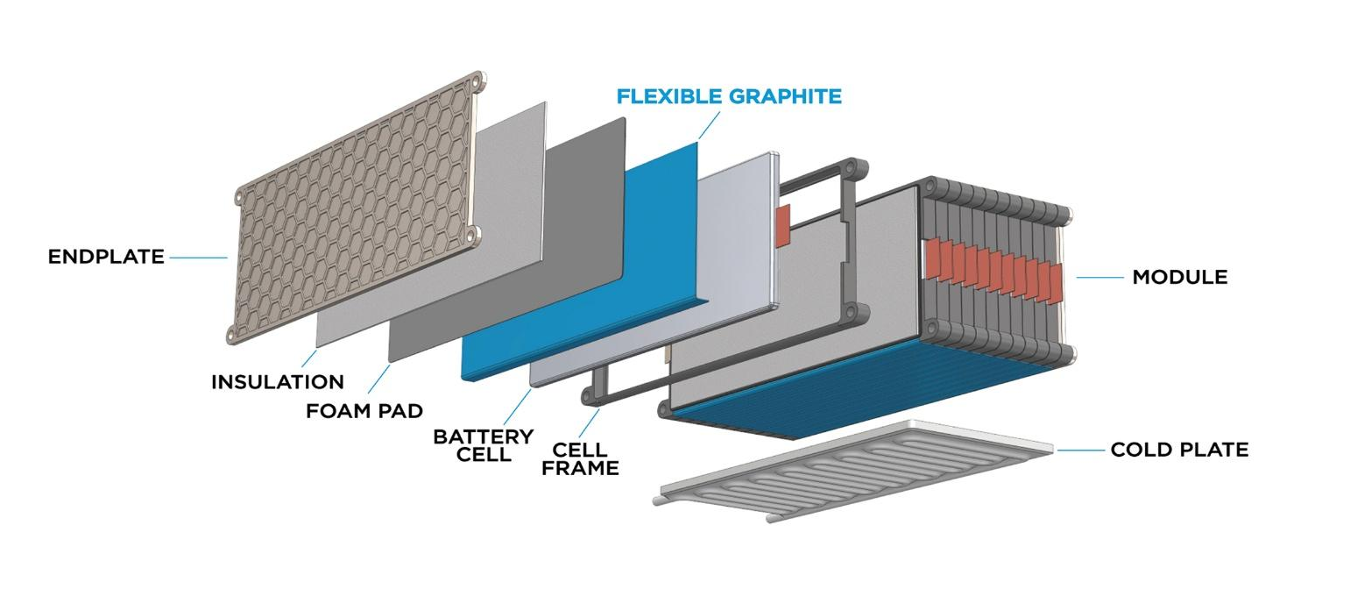

SpreaderShield flexible graphite cooling fins are designed to attach directly to pouch and prismatic cells using the included pressure-sensitive adhesive. Additionally, a foam pad is often installed between cells to maintain consistent pressure between the graphite and the cell. The graphite evenly distributes heat across the cell, reducing hot spots and extending the cell’s lifespan. It then transfers excess heat to the cold plate or heat sink, dissipating heat into the surrounding environment.

By efficiently spreading heat and dissipating it to the cold plate, the cell temperature is effectively controlled during fast charging and discharging cycles. This tight temperature regulation enables the pack to be charged as quickly as the cell chemistry and charger power allow.

If propagation control is needed, graphite works with an insulating layer to prevent heat from spreading to surrounding cells in case of a failure. Cell-to-cell or module-to-module propagation control can be easily achieved. Please consult a NeoGraf Solutions Applications Engineer for more design information.

In the Best Practice battery pack illustration (show below), graphite is placed directly against the pouch cell and bent around the bottom of the cell to provide a direct heat path to the cold plate. A layer of foam accommodates tolerances as the cell expands and contracts. An outer layer of insulation and impingement protection shields neighboring cells from overheating in the event that a cell fails.

Figure 1

SpreaderShield™ Certifications

SpreaderShield flexible graphite cooling fins are made entirely of graphite (carbon) and wrapped in thin dielectric PET plastic laminates and meet the following standard environmental and chemical requirements.

- RoHS

- REACH

- UL 94 V-0

- Lead / Halogen-Free

- Conflict-Free

Conclusion

SpreaderShield allows module and pack designers to create lightweight, compact battery packs that offer superior thermal management. Using flexible graphite enables faster charging, longer driving range, and extended cell life.

# # # #