The UAV (unmanned aerial vehicle), and eVTOL (electric take-off and landing) industries have experienced significant growth over the past decade, driven by advancements in technology and increasing applications across various sectors, including military, agriculture, logistics, surveillance, and entertainment. These advancements have led to improved performance and safety of UAVs and eVTOLs, including the critical battery systems that power these aerial vehicles. The engineers and the R&D team at NeoGraf Solutions, continue to find the best graphite thermal management solutions for this rapidly evolving market.

Managing batteries’ thermal characteristics is crucial in ensuring their efficiency, longevity, and safety. This article will examine the significance of thermal management, in which NeoGraf has vast experience and product knowledge in drone batteries, including various cooling techniques and their impact on performance. NeoGraf offers many different thermal management solutions such as SpreaderShield™ flexible graphite heat spreaders, HiTherm™ thermal interface materials, and NeoNxGen® thermal management solutions.

Importance of Thermal Management

Batteries used in UAVs & eVTOLs, particularly lithium-ion batteries, are susceptible to temperature fluctuations. High temperatures can lead to accelerated degradation of battery cells, reduced capacity, and even catastrophic failures such as thermal runaway, which can result in fires or explosions. Conversely, low temperatures can lead to decreased battery performance and reduced flight times.

Effective thermal management ensures that batteries operate within an optimal temperature range, typically between 20°C to 30°C (68°F to 86°F). Maintaining this range is essential for:

- Safety: Preventing overheating and potential hazards associated with battery failure

- Performance: Enhancing power output and efficiency during operations

- Longevity: Extending the battery’s lifespan and reducing operational costs associated with replacements

Thermal Management Techniques

Various techniques are employed to manage the thermal characteristics of UAV batteries, including passive, active, and hybrid methods.

- Passive Cooling: This method utilizes materials and designs that facilitate heat dissipation without requiring external power. Examples include aluminum casings and thermal interface materials that enhance heat conduction.

- Advantages: Low cost, low energy consumption, and minimal complexity

- Disadvantages: Limited effectiveness in high-temperature environments and under heavy loads

- Active Cooling: Active cooling systems utilize fans, pumps, or other mechanical devices to enhance heat dissipation. This method may involve liquid cooling systems or forced air cooling.

- Advantages: More effective at maintaining optimal temperatures, especially in high demand scenarios

- Disadvantages: Increased energy consumption and potential mechanical failure points

- Hybrid Systems: By combining passive and active cooling methods, hybrid systems aim to optimize thermal management by leveraging the strengths of both approaches.

- Advantages: Improved thermal performance and flexibility in various operational conditions

- Disadvantages: Complexity and higher initial costs

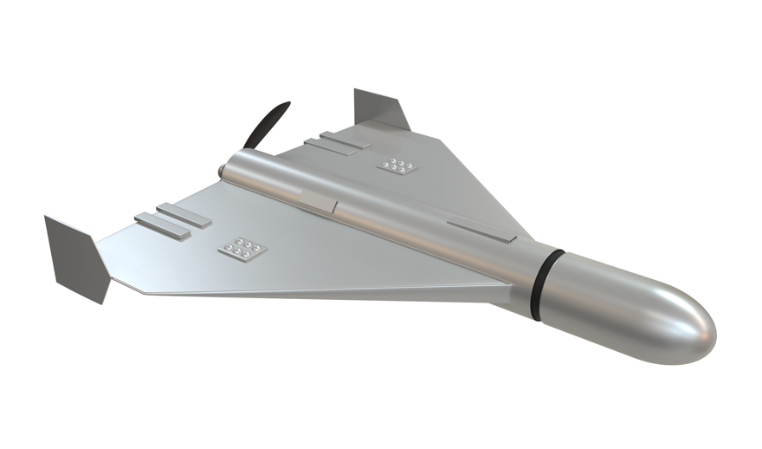

Battery-Powered UAVs and eVTOLs

Battery-powered UAVs and eVTOLs have unique requirements to ensure that the batteries used in these vehicles perform to their highest capabilities yet do not pose a safety hazard to passengers or equipment. The biggest issue when dealing with aviation batteries has to do with heat. Charging, discharging, or even normal flight operations can produce heat in amounts that will cause hot spots in the cells. This uneven distribution of heat results in the shortening of useful cell lifetime or, in extreme cases, can lead to a cascading failure where every cell in a module catches fire in a thermal propagation event, also known as thermal

runaway.

NeoGraf’s SpreaderShield™ flexible graphite heat spreaders efficiently eliminate hot spots from the cells and then spread them to an outside heat sink. Building on a long and successful history in the EV and maritime industries, SpreaderShield flexible graphite is a lightweight, thin, and permanent thermal solution.

Case Studies

- Agricultural UAV: In precision agriculture, UAVs are used for crop monitoring and pesticide spraying. These operations often require sustained high-performance levels, leading to increased thermal generation. Such UAVs have implemented active cooling solutions to ensure batteries remain within optimal temperature ranges, resulting in longer operational times and improved safety.

- Delivery UAV: Many companies, like Amazon, are exploring UAV delivery systems. These drones require lightweight and efficient battery systems. Hybrid thermal management systems can ensure that the batteries perform efficiently during peak operational hours while preventing overheating during charging cycles.

Conclusion

As the UAV &eVTOL industries continues to evolve, the importance of effective thermal management in battery systems cannot be overstated. NeoGraf is ready with practical solutions for the increasing demands of longer flight times, enhanced safety, and reliability. Manufacturers must invest in innovative cooling techniques to optimize battery performance. Whether through passive, active, or hybrid methods, managing the thermal characteristics of batteries will play a pivotal role in the future of UAV & eVTOL technology. The continued research and development in this field will enhance operational efficiency and pave the way for more advanced applications of drones across various industries.

# # # #

Author: Ken Dworznik – NeoGraf Solutions Senior Sales Manager